Container ship revolution by BRIAN J. CUDAHY

Browsing through a general-purpose bookshop section on “Transport by Sea” would lead to titles on the stately passenger liners of yesteryear, old-fashioned paddle-wheel steamboats, luxury cruise ships, and warships of every shape and size. Few, if any, volumes would cover the seagoing merchant vessels that exercise enormous influence on the national economy—cargo ships. Overseas trade has assumed unimaginable proportions in the past half century. Although some commodities are transported most readily by air, and some high-value cargo such as software can travel from continent to continent electronically, the great bulk of world trade is carried across the seven seas by cargo ships. Many commodities are transported in bulk, and specialized vessels have been developed to accommodate this trade. Fleets of giant tankers move petroleum products from producers to consumers, and similar vessels carry such diverse cargo as cement, coal, and grain. The automobile industry has developed the car carrier, a unique vessel that allows vehicles to be driven on and off the ship, and other kinds of large and high-value commodities typically travel on flatbed trailers aboard similar roll on–roll off vessels. Just about everything else—from boxes of crayons to crates of cereal, television sets to garden tools, model railroad trains to baseball gloves, men’s shirts to women’s shoes—travels across the sea fro

m factory to market aboard fleets of huge containerships. These vessels have played a critical role in allowing the world’s economy to assume global dimensions.

A Vision Takes Shape

To understand how and why the modern containership evolved, turn back the calendar to Thanksgiving week in the prewar year of 1937. The owner of a small trucking firm in North Carolina had ventured north to New York harbor with bales of export cotton to be loaded aboard a ship bound for Istanbul. The man grew irritated when he had to wait for days while longshoremen slowly loaded cargo aboard the vessel. In those days, a cargo ship typically would spend as much time in port being loaded and unloaded as it did sailing the seven seas. Cargo included a bewildering variety of merchandise that had to be hoisted aboard ship in small lots and then painstakingly stowed in the hold in a manner that would forestall damage during the ocean journey. The operation was time-consuming and labor-intensive.

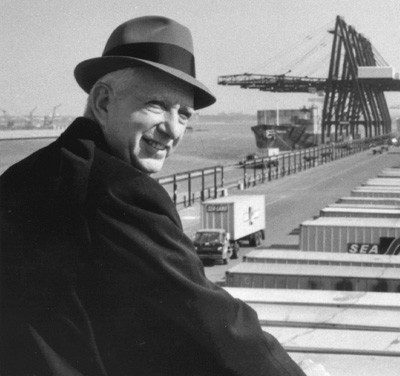

Furthermore, because of the uncertainties of steamship schedules, outbound cargo often was delivered to a pier days and even weeks ahead of the presumed sailing date, increasing the chance of damage, loss, and pilferage. One steamship executive suggested that it cost his company more to move cargo 1,000 feet from the street in front of a pier into the hold of a moored ship than it did to transport the cargo thousands of miles across a hostile ocean. The North Carolina truck driver often said to anyone who would listen, “There has to be a better way than loading cargo aboard ship piece by piece. Why couldn’t an entire truck be hoisted aboard ship, for instance, and then used for delivery purposes at the other end of the line?” The frustrated trucker had begun to think about the implications of intermodalism, a word that in 1937 was decades away from being coined. That man was Malcom McLean, and his North Carolina–based trucking company would grow into one of the nation’s premier over-the-road cargo operations, McLean Trucking. McLean, however, kept thinking about his experience in 1937 and the inherent limitations of loading cargo aboard ship. On a rainy April Thursday in 1956, he did something about it.

The North Carolina truck driver often said to anyone who would listen, “There has to be a better way than loading cargo aboard ship piece by piece. Why couldn’t an entire truck be hoisted aboard ship, for instance, and then used for delivery purposes at the other end of the line?”

The First Containerships

A vessel bearing the unusual name Ideal X was a run-of-the-mill T-2 tanker, similar to countless others that moved petroleum from the Texas oil fields to northern refineries. But when Ideal X cast off from Berth 24 at the foot of Marsh Street in Port Newark, New Jersey, on April 26, 1956, and set a course for Houston, Texas, it was more than another tanker heading south in ballast to pick up additional product. Installed above the vessel’s main deck was a special spar deck—a raised platform or porch—with longitudinal slots to which were attached the bodies of 58 trailer trucks. These were not trucks in any conventional sense—the 58 units had been detached from their running gear on the pier and had become containers. Arriving in Houston six days later, the 58 trailers were hoisted off Ideal X, attached to fresh running gear, and delivered to their intended destinations with no intermediate handling by longshoremen. McLean had orchestrated a pioneering voyage. In preparation, he had acquired a small steamship company in early 1955 to convert into an adjunct of his trucking enterprise. Based in Mobile, Alabama, the Pan Atlantic Steamship Company was founded in 1933 and was a subsidiary of the Waterman Steamship Company. McLean soon acquired the parent company also, although Waterman eventually would move out of McLean’s control and resume an independent identity. Pan Atlantic, however, would evolve into what many knowledgeable maritime observers would call the most important and most successful deepwater steamship company to operate as part of the U.S. Merchant Marine.

Sea-Land Service

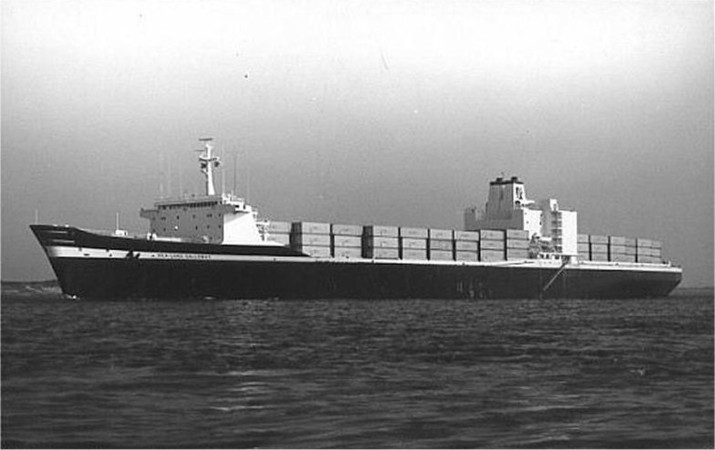

In 1960, McLean hauled down the blue-and-white Pan Atlantic house flag and renamed his maritime venture Sea-Land Service. Although Ideal X and three other converted T-2 tankers that entered Pan Atlantic service in 1956 are often called the world’s first successful containerships, the basic design features that characterize the modern containership were not introduced until 1957.

Design Innovations

On October 4, 1957, the Soviet Union launched Sputnik I, the world’s first earth-orbiting satellite. On that same day, the Pan Atlantic ship Gateway City steamed away from Port Newark and headed south to Miami, then on to Houston. Ideal X had transported containers that were individually attached to a flat spar deck, but Gateway City, a World War II cargo ship identified as a C-2 Class vessel, had been thoroughly rebuilt to stack containers one atop another in below-deck racks and to haul additional units stacked atop each other as deck cargo. The 524-foot Ideal X could handle 58 trailers, but the 450-foot Gateway City could accommodate 226. In many respects, the voyage of Gateway City signaled the onset of the contemporary containership era. Five sister ships soon joined the 1957 pioneer in McLean’s fleet, and the spar deck tankers of 1956 were retired. All manner of older cargo ships were converted into exclusive container carriers, and Sea-Land quickly developed a basic design feature of contemporary containerships—a deck house located well to the stern of the ship, a large open area with container-carrying holds between the deck house and bow, and room for additional containers aft of the deck house.

Expansion and Competition

McLean expanded his waterborne operations to Puerto Rico in 1958, to the West Coast via the Panama Canal in 1962, and north to Alaska that same year. In the meantime, other U.S.-flag steamship companies began to explore the opportunities of containerization. Matson Navigation Company inaugurated container service between California and the Hawaiian Islands in 1958, and Grace Line put its first containerships into service between New York and Venezuela in 1960. Nevertheless, many of the more traditional oceangoing steamship operators—in particular, important European companies such as Holland America and Cunard—regarded containerization as appropriate only for select domestic niche markets. To them, the innovation had no place along such classic international trade routes as the North Atlantic. After April 1966, however, the companies held that view at their own corporate peril. Sea-Land’s Fairland, a converted C-2 cargo vessel and a sister ship of Gateway City, left Port Newark for the Channel ports of Europe. More than the pioneering container voyages of 1956 and 1957, Fairland’s North Atlantic crossing signaled the demise of the conventional cargo ship and of the lengthy stays in port to load and unload cargo.

Advantages and Adaptations

The containership offered important advantages to both shipper and steamship operator. Freight was securely loaded aboard a trailer at the shipper’s factory, its doors sealed, and the consignment dispatched to a nearby port city. There the cargo remained secure while awaiting the ship that would transport it across the sea. Furthermore, because the containers were hoisted on and off ship by swift gantry cranes, stays in port that once were measured in days and weeks were reduced to hours. The shipper benefited from decreases in pilferage and damage, and the operator gained more efficient and effective use of ships and maritime personnel. Many critical challenges arose along the way. How the trucking and maritime industries developed a set of standards for the design of containers and associated hardware such as gantry cranes is a story in itself. Organized labor had to be convinced that waterfront workers would face a better and more secure future by thinning the ranks to take advantage of the efficiencies of containerization. Another part of the containership saga is the reconfiguring of port facilities around the world to handle inbound and outbound containers efficiently. The covered piers and storage sheds that protected cargo from the weather before hoisting aboard ship were replaced by large open tracts of land, where teamsters could position trailers to move on and off the ship via huge gantry cranes. In the wake of Fairland’s transatlantic voyage of 1966, replacing conventional cargo ships with new container-carrying tonnage became the goal.

Reaching Southeast Asia

McLean’s Sea-Land Service remained the pacesetter of the containership industry, and the company continued to expand its fleet of U.S.-flag vessels and to open up new services. In the late 1960s McLean was able to tap an interesting market—moving supplies to and from South Viet Nam for the U.S. military. McLean convinced the military that containerization could solve many troublesome problems associated with maintaining an effective chain of supply. McLean and his representatives made the case that waterfront theft from conventional cargo ships in Viet Nam was so serious that a hefty percentage of inbound material was winding up in enemy hands. Just as containerization was able to reduce dockside pilferage in U.S. ports, so too it could thwart efforts by Viet Cong sympathizers to steal war material intended for U.S. soldiers. McLean also was aware that a considerable portion of traditional manufacturing was shifting from North America to Asia. Because vessels bound for Viet Nam were returning to North America largely empty, McLean established a triangular trade from the West Coast to Viet Nam with war supplies, from Viet Nam to Japan and Hong Kong empty, and then back across the Pacific with commercial cargo from Asia to North America. When transpacific trade assumed an important role in Sea-Land operations, McLean teamed up with Southern Pacific Railroad to develop the first double-stack freight car for carrying containers inland from West Coast ports. The implications and impacts of the Viet Nam War continue to be debated. Nevertheless, the transpacific logistical supply line that was established in support of the war provided another dramatic example of the efficiencies of containerships.

The Magnificent SL-7s

In 1972, Sea-Land took delivery of eight new containerships with extraordinary specifications—ships that would be fast enough to cut full days from the transatlantic and transpacific crossing times. Two different European yards turned out the SL-7 Class.2 The eight SL-7s that joined the Sea-Land fleet could maintain 33 knots—10 to 15 knots faster than any other cargo ship then in service. The superliner SS United States may ha

ve wrested the transatlantic speed record from the Queen Mary in 1952, but the Sea-Land Exchange, one of the SL-7s, crossed the North Atlantic in August 1973 at 34.92 knots, only 0.97 knots slower than the United States. Another SL- 7, Sea-Land Commerce, is the all-time speed champion in the transpacific merchant trade. In addition to being fast, the SL-7s also were the world’s largest containerships at the time. Gateway City and the other converted C-2 cargo ships of 1957 could accommodate 226 trailers each. Each SL-7 was able to carry more than 1,000 containers. Containerships typically are compared in terms of carrying capacity. Because a 20-foot container is the smallest in common use, vessels are measured in TEUs, trailer-equivalent units or 20-foot-equivalent units.

A 1,000-TEU containership therefore can accommodate 1,000 20-foot containers or 500 40- foot containers. Sea-Land was something of a renegade, employing a large fleet of 35-foot units, which made precise comparisons difficult, although the company soon shifted to more conventional trailers.

As built, an SL-7 could accommodate 896 35-foot containers plus an additional 400 TEUs. The new fleet proved to have a liability. To maintain the design speed of 33 knots, the boilers that generated steam to drive the dual turbine engines burned an extraordinary quantity of fuel. At pre- 1972 price levels, this would not have been a problem, but 1973 brought the first of several worldwide petroleum crises that caused the price of petroleum to increase at an unprecedented rate. The company throttled back its fleet to conserve fuel, and the eight vessels became a luxury that a commercial operator could not afford. The company sold off its prize vessels to the U.S. Navy in 1981 and 1982, and they remain in service for the Department of Defense as T-AKR Class fast supply ships.

Parting Company

Following the advent of the SL-7 in 1972, Sea-Land Service began an interesting corporate evolution. McLean had sold controlling interest in the line to R.J. Reynolds in 1969 to gain the investment capital to move the SL-7 into production. Several years later he severed his ties with the company. McLean later acquired United States Lines and returned to the containership industry. But new and different currents were affecting the maritime industry, and much of the U.S. Merchant Marine faced the same kind of outsourcing and shifting to offshore operations that were prevalent in many other commercial sectors. In 1999, after a short period of ownership by the CSX Corporation, Sea-Land Service, nee the Pan Atlantic Steamship Company, was sold to a Danish conglomerate, the A.P. Moeller Group, and the world’s pioneer containership operation was absorbed into the Maersk Line, the largest containership fleet in the world.

Extraordinary Evolution

The economies of scale that motivated Sea-Land and McLean to build ever-larger containerships continue to prevail in the now-global industry. On April 26, 2006, the 50th anniversary of the departure of Ideal X from Port Newark with a capacity load of 56 trailers, containerships in service under operators such as Hapag-Lloyd and the Mediterranean Shipping Company had passed 9,000 TEUs, with 10,000-TEU vessels certain to follow. The first 50 years of the containership era can be viewed through different prisms. Naval architects and merchant seamen may concentrate on the extraordinary evolution of containership design that has progressed from the converted T-2 tanker Ideal X and the C-2 cargo ship Gateway City to vessels with capacities approaching 10,000 TEUs. Shippers may marvel at the wonders of “just in time” chains of international delivery that bring products to market with extraordinary efficiency. Transportation planners may grow exasperated as they seek to develop more seamless links between seaports, highways, and railways, and port officials may wonder how they will find the resources to adapt their harbors for the ever-larger containerships. Economists and political scientists may continue to measure and assess the implications of a global economy in which the clothes and backpacks worn by youngsters heading to school in Middle America were manufactured in factories in the Far East and transported across the Pacific aboard containerships that fly flags of many countries, but rarely that of the United States. One can only wonder how things might have turned out if longshoremen in Jersey City had managed to unload a truckload of cotton with greater dispatch during Thanksgiving week of 1937 and sent a trucker home to North Carolina with nary a frustration.

Copyright, Transportation Research Board of the National Academies, Washington, D.C.

Listen to a 9 minute podcast on the evolution of the shipping container here.