Boom greasing is important to keep your crane in optimal condition, to ensure performance, and maximise your return on investment.

Smooth boom operation on a telescopic crane is a fundamental requirement for all lifting duties.

To improve safety, longevity, and ease of operation Manitowoc’s maintenance procedures include a detailed schedule for boom greasing.

Depending on the crane type and model the procedure to follow and the periodicity of lubrication may differ, concise instructions can be found in the service manuals for each model.

Manitowoc specifies the lubricant to be used in/on each specific case and component on the crane, for example, the use of semi-synthetic lubricants as opposed to mineral or fully synthetic lubricants in certain areas/components may affect the periodicity of lubrication or end up damaging the component if the correct specification and formulation are not used.

Failure to follow the proper setup of the crane for lubrication may result in the crane tipping over and/or unintended damage.

To aid the efficient application of grease Manitowoc has developed some special tools to aid the process.

Have a look at this Bulletin and information on Boom Grease Plus from Manitowoc.

Regular preventive maintenance ensures good crane reliability.

The right tools can make all the difference and help to make regular maintenance quick and trouble-free!

Get as a kit or individually.

Any questions, feel free to contact our parts team at: parts@patersonsimons.com

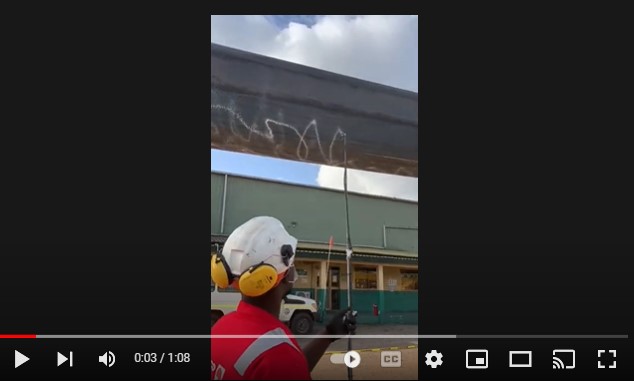

Have a look at the team in action here: