The Manitowoc factory in Shady Grove, Philadelphia, USA produces Rough Terrain Crane, Industrial Crane and Lattice Boom Crawler Crane lines for Manitowoc/Grove.

During a recent visit to the Shady Grove facility Paterson Simons staff spent some time with the Product Verification Team, here a few highlights of thier ground-breaking work.

The Product Verification Center (PVC), launched by Manitowoc in 2012, interacts with many key areas of the business (procurement, design, manufacturing, warranty and field service input from dealers such as Paterson Simons) and we believe the PVC is unique in the industry in driving up standards of quality. The Shady Grove PVC is the first of three built by the Manitowoc Group, the others are in Wilhelmshaven Germany, for All Terrain GMK products and in Lusigny, France, for Tower Crane products.

In these facilities Manitowoc tests cranes and components to destruction by replicating extreme conditions and typical working cycles over time. The work brings up the quality, not just of internally designed components and structures, but also of those from third parties where Manitowoc works with sub-component suppliers to improve quality of existing components.

Mobile cranes, particularly those sold outside of the rental sector, generally have long lifetimes, well beyond those of machines working in a production environment (Paterson Simons routinely services 25+ year old equipment) and bought in sub-components are generally not designed with that kind of lifespan in mind. Through the initiatives of the PVC, Manitowoc is ensuring cranes are as reliable as possible over protracted timescales.

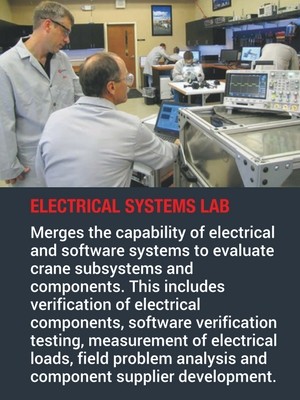

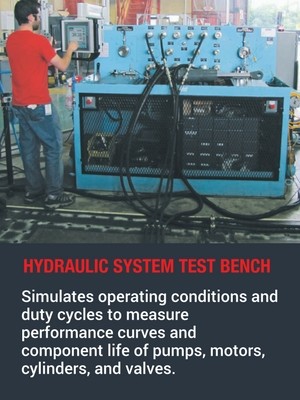

The team working within these facilities are well-resourced with an array of tools, test benches and both indoor and outdoor facilities coupled with an obvious enthusiasm for the work they do.

See the more on the work of the PVC on the video below.