Konecranes Inverters lie at the heart of their world-leading RTGs. The precise movement of the cranes is safely and intelligently controlled through these hard-working components. In process cranes like RTGs, these inverters that simplify the motion of the crane, are doing a lot of hard work in the background so it is inevitable that they are subject to wear and tear that eventually will require their replacement.

Options to replace have been limited to outright replacement with new units or refurbishment at the Konecranes factory with long wait times, administration and transport costs and shipping delays.

Paterson Simons has worked with Konecranes to bring those refurbishments closer to the market and following an investment in tooling and training, we are pleased to announce our Konecranes accredited inverter repair workshop!

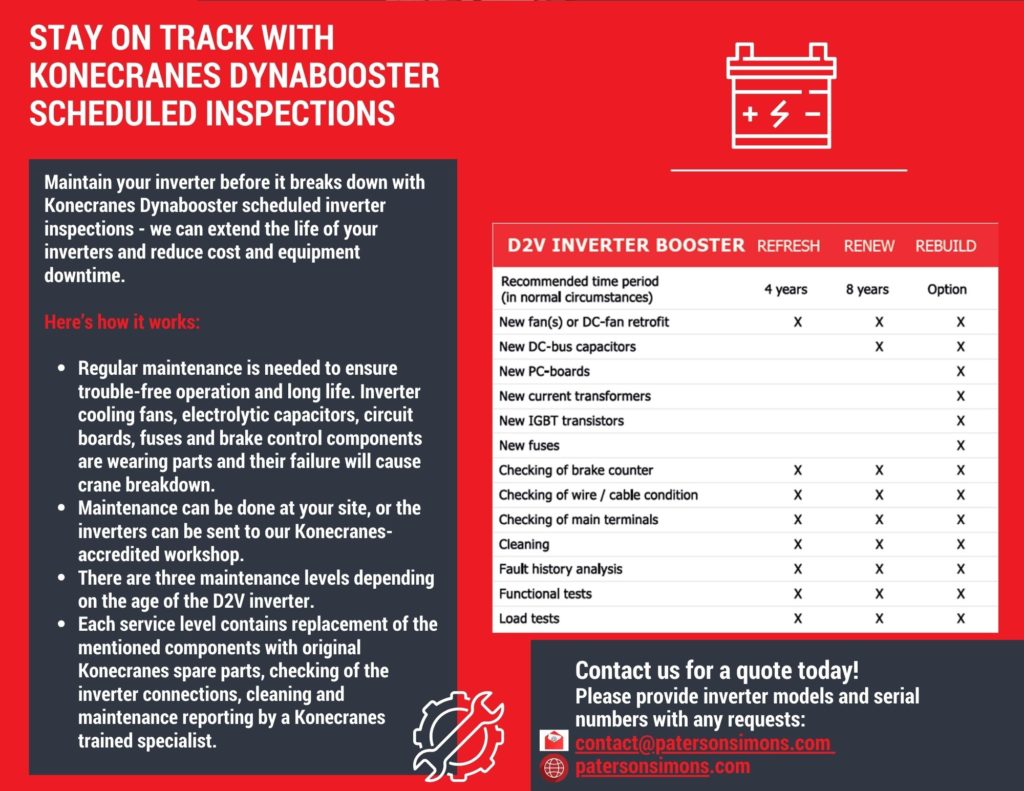

STAY ON TRACK WITH KONECRANES DYNABOOSTER SCHEDULED INSPECTIONS:

We can extend the life of your inverters and reduce cost and equipment downtime! See detail below:

WHAT ARE THE MOST COMMON REASONS FOR INVERTER REPAIRS?

THE FOLLOWING ITEMS ARE CHECKED DURING AN INSPECTION:

Paterson Simons is the sole provider of approved Konecranes-accredited Inverter Repairs (outside of Konecranes).

Contact us for a quote today!

Please provide inverter models and serial numbers with any requests:

Contact us here